Applications

Product Flow & Control

What Is Product Flow?

Ensuring a continuous flow of products through the line is essential for maintaining efficiency and maximizing throughput. To achieve product flow, various methods and components are needed to keep the line running smoothly across each part. Product flow will vary greatly depending on the product itself, its flow path, and the equipment used at each part of the process.

What Role Do Conveyors Play in Product Flow?

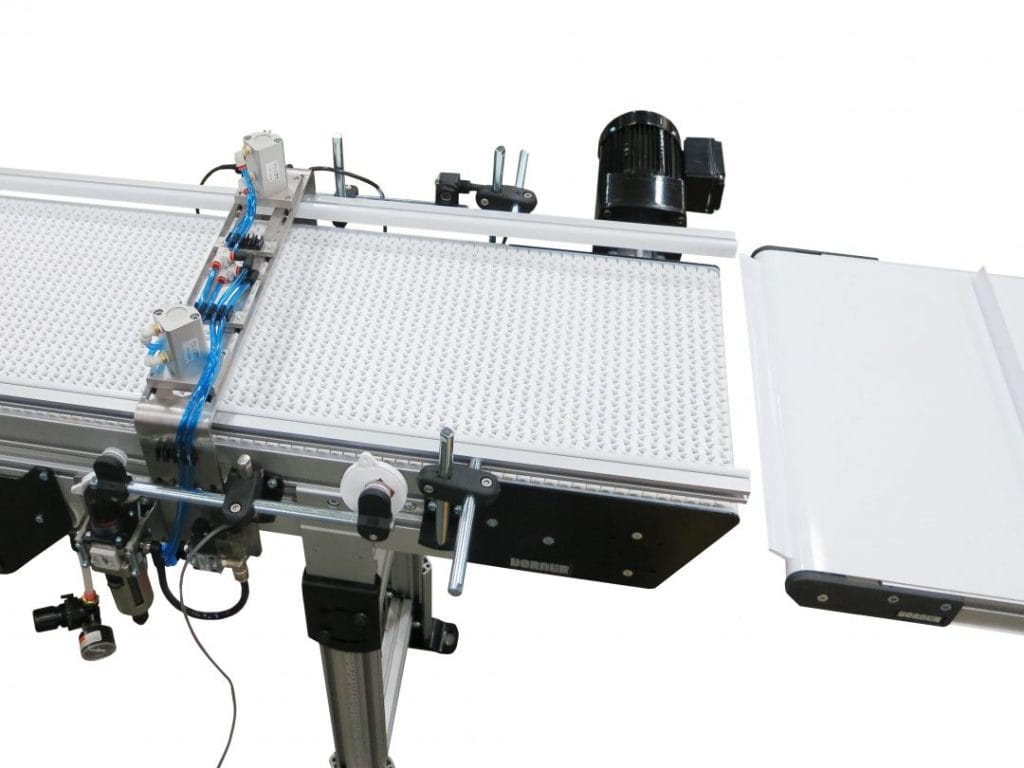

The equipment used in product flow plays a crucial role in how smoothly the line runs. Conveyors are integral to product flow as they can be configured on a custom basis depending on manufacturing requirements. The configuration of the conveyor, coupled with the automation and speed that it offers, can significantly improve efficiency and process.

What Are Other Factors in Product Flow?

There are several other factors in product flow to consider, such as internal operations and processes. Conveyors are an important part of the equation, but processes and operations also need to be evaluated to ensure that product flow is smooth, easy, and error-free.

Examples of How Conveyors Improve Product Flow

Conveyors improve Product Flow in numerous ways and offer significant value throughout the process.

Conveyors automate the movement of goods, accelerating Product Flow. Time, cost, and labor are therefore reduced due to automation, and more products move through the flow faster.

Product Flow is also improved through the use of conveyors since the equipment improves reliability and accuracy. In addition, product flow can move more smoothly since there is less manual work required in checking and rechecking different parts of the flow.

Furthermore, conveyors can help maximize floor space and can be configured to fit manufacturer needs. The product flow can run smoothly with a conveyor without impacting other equipment that is needed.

Product Flow and Control Options

There are several product flow and control options available, depending on requirements and needs. Each option provides significant advantages for customers looking to boost efficiency. Product flow and control options are useful for creating a smooth product flow process.

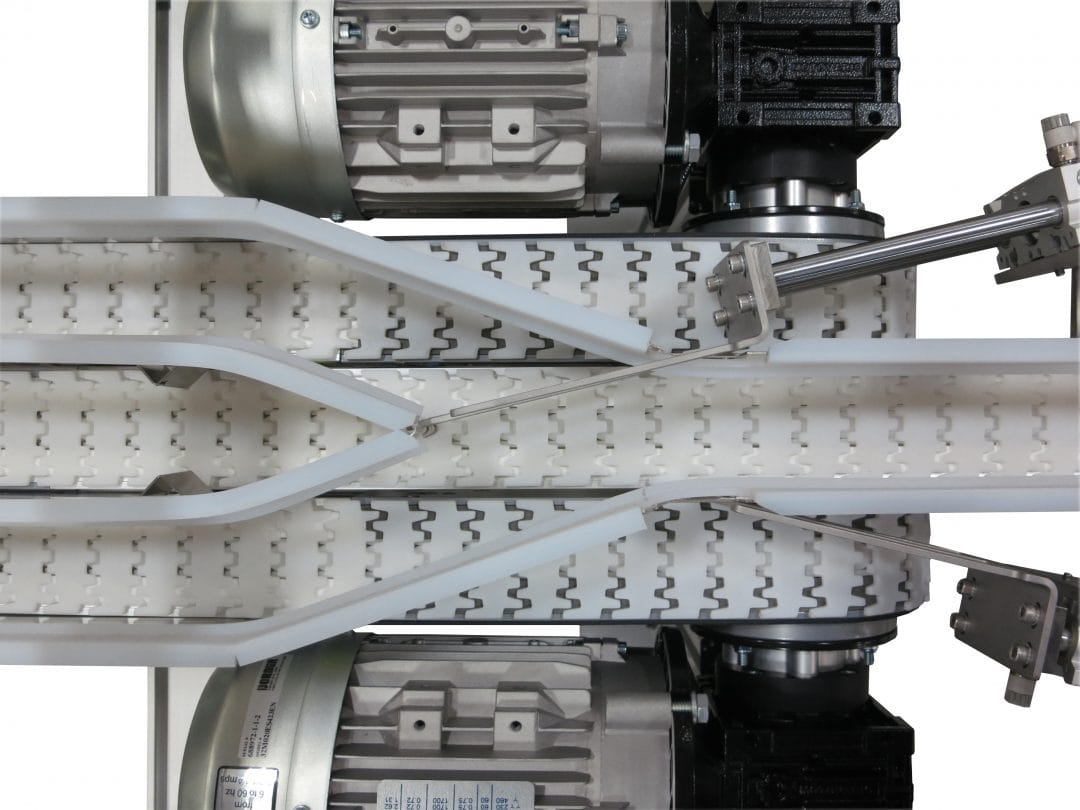

Diverters and Gates

Diverters and gates are useful for diverting and moving products from one lane to another. Diverters and gates can be used to split product flow based on process, and machine availability and are used to automate product movement to increase product flow speed.

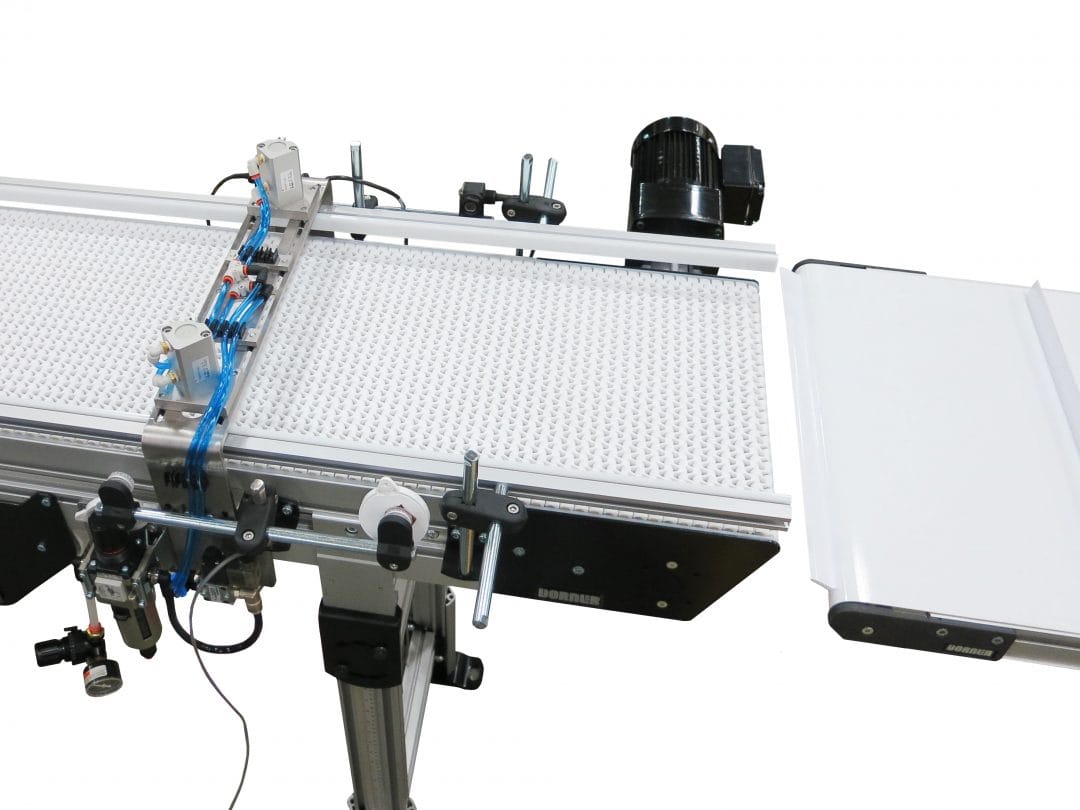

Lane Guiding

Lane guiding moves products from one central lane into several other lanes, detecting products based on sizes to ensure the flow remains undisrupted. Lane guiding can help distribute products into different lanes more efficiently, without blocking products as lanes are changed.

Pushers

Pushers are useful when products must be moved off the conveyor in a perpendicular flow. Pushers can also be used if products are particularly heavy, as they ensure that products are pushed during the flow to keep product flow moving steadily.

Considerations When Determining Product Flow Process

The product flow process will vary depending on a few different factors. However, by identifying key considerations early on, you can develop a product flow process that works well and maximizes efficiency.

Weight of Product

Other Product Characteristics

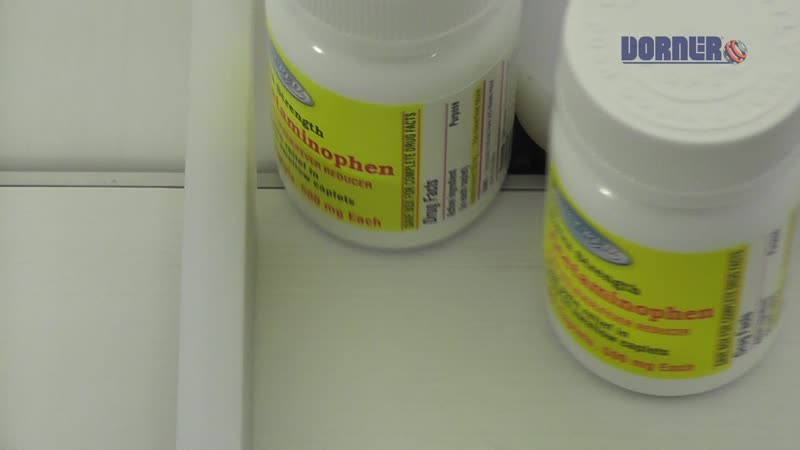

Sanitary Concerns

Sanitation is a core function of the product flow process, especially for food and beverage products. The product flow process needs to incorporate sanitation and safety into the flow and identify how equipment can help. Being mindful of FDA and other regulatory body concerns is also crucial.

Direction of Product Movement

Based on the direction of the product movement, the product flow process will have to change. For example, a perpendicular flow may require more specialized conveyors and control options such as pushers. However, other directions of product movement, such as multiple lanes, may require different configurations such as diverters and gates.

Length of Line

The length of the production line will also be a major consideration for the product flow process. A longer product line will need more flow and control options to keep the product line running at optimal throughput. Additionally, automation will be needed to ensure that each part runs smoothly without impacting the step ahead.

Speed

One of the main goals for the product flow process is to increase speed while decreasing the risk of irregularities and issues. Therefore, product flow processes need to consider each step and equipment needed to speed up the process without increasing manual labor.

Bearings

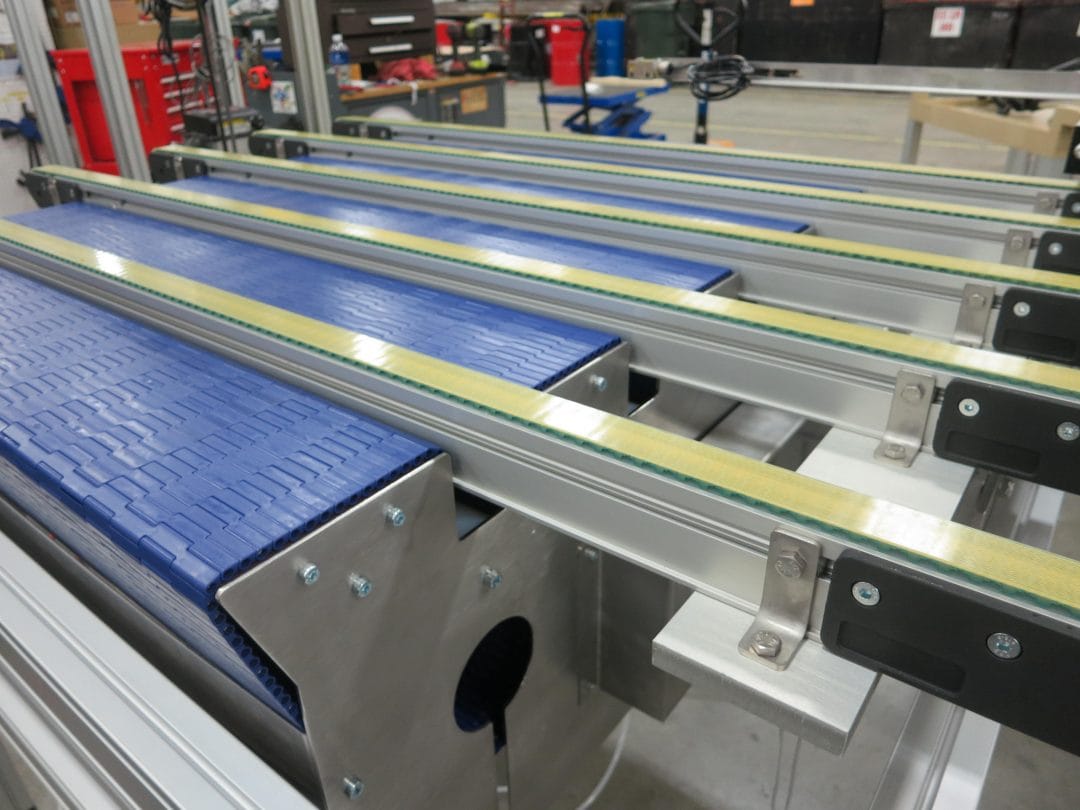

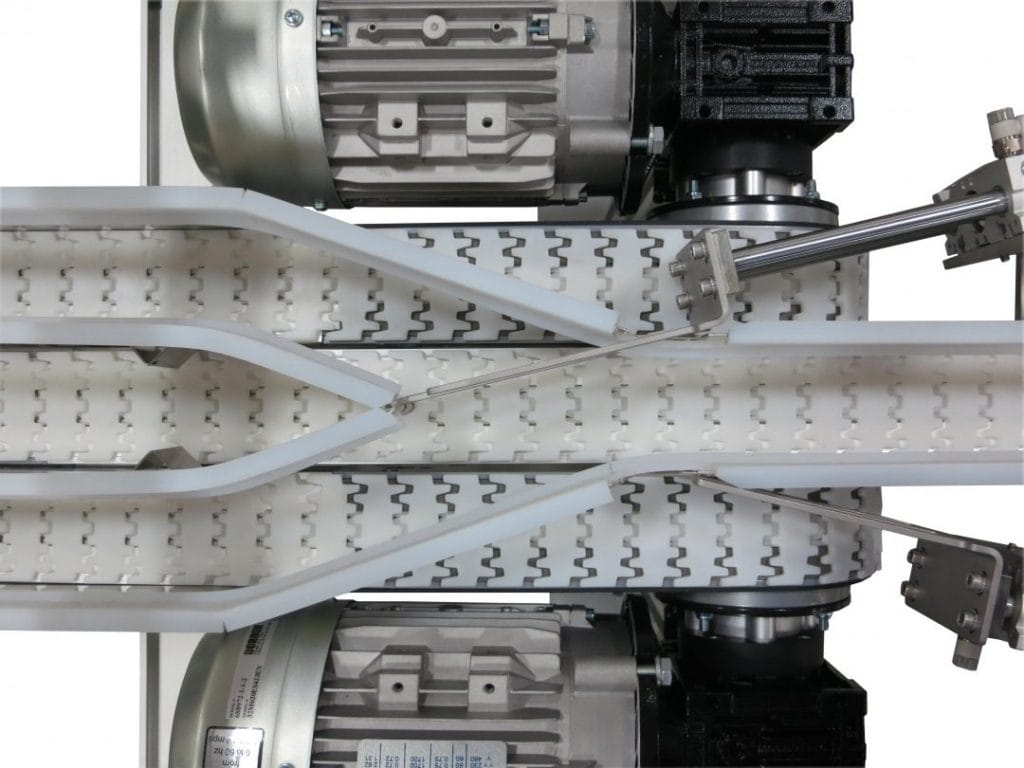

Type of Belt

Based on product characteristics and the product flow mapped out, another consideration needs to be the type of belt used to ensure products move quickly and without error. Factors such as sanitation control will also require more specific types of belts that automate different types of functions.

Frequently Asked Questions About Product Flow and Control

How Do Dorner Conveyors Improve Product Flow?

Dorner Conveyors improve product flow by creating specific types of equipment to match manufacturing requirements. Based on the product flow process and the type of control needed, Dorner conveyors offer a wide selection of conveyors to match needs.

Can I Improve Product Flow on Curved Conveyors?

Product flow can be improved on curved conveyors using product flow and control options such as pushers, diverters and gates, and lane guiding.

What If I Want to Improve Product Flow But Have Special Sanitary Requirements?

Dorner conveyors are stainless steel conveyors specifically designed for sanitary applications. Dorner conveyors use FDA-approved belting and plastic components and do not include horizontal surfaces to ensure cleanliness.

How Do I Train My Team to Use Dorner Conveyors?

For certain situations, we offer on-site maintenance training from the Dorner staff. We’ll help your team better understand how to take care of conveyor equipment and increase productivity.