- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Find the Right Automation Conveyor

Assembly and Industrial Automation

For years, our Dorner conveyor experts have been developing and producing cutting-edge systems for assembly and industrial needs. These precision move pallet systems are flexible, accurate, versatile, and easy to use. The unique design behind these systems gives them a competitive advantage when it comes to increasing efficiency and decreasing downtime. Our automated systems are proven to reduce costs while saving time and resources with proper configuration. In fact, here at Dorner, we set the industry standard for systems designed around unit handling automation challenges.

Pallet Systems and Precision Move

Don’t leave conveyor automation to chance. Take control with our pallet systems and precision move technology in automation. There are many benefits to applying Dorner’s assembly and industrial automation conveyor technology, such as:

- Versatile layout flexibility

- Flexible chains

- Accuracy in positioning and routing

- Easy design changes

- Improved production line efficiency and generation

Our pallet systems provide unique flexibility with extended benefits; line configurations range from high load capacities to quick belt changes and cleanroom certifications. Get accurate positioning and routing with our precision move and pallet systems, designed to streamline assembly processes and inspections.

The assembly automation market has driven us to create machines that drive automation. Our 2200 Series Precision Move Pallet System conveyor and our FlexMove Pallet Systems are advanced in pallet traffic management and are specifically designed to increase efficiency, reduce downtime in automation processes, and provide the accurate conveying.

Our systems come in kits for those interested in customizing their installation. With our DTools configuration process, you can control each step of the design process from choosing materials to selecting a layout.

Automated Conveyor Solutions

With years of experience, we’re ready to help even if your line faces unique challenges due to difficult or unwieldy product packaging, assembly, industrial, sanitation, incline, or product inspection challenges. We offer a wide selection of product and conveyor solutions that includes: product repositioning conveyor technology, magnetic belt for easy line transportation, or smaller conveyors that work best for line integration. When it comes to fitting your conveyor needs, Dorner has the solution.

In Need of a Custom Conveyor Build?

All of our products are designed and tailored to fit all your automation needs. For a full list of our Dorner conveyor products, see our Engineered Solutions Page.

Our conveyors are found in fast-paced production lines around the world. When your assembly line is running smoothly and performing efficiently, your company can move faster and smarter. To find out more about Dorner’s professional automation services, call us today at 1-800-397-8664.

Automation Conveyor Solutions

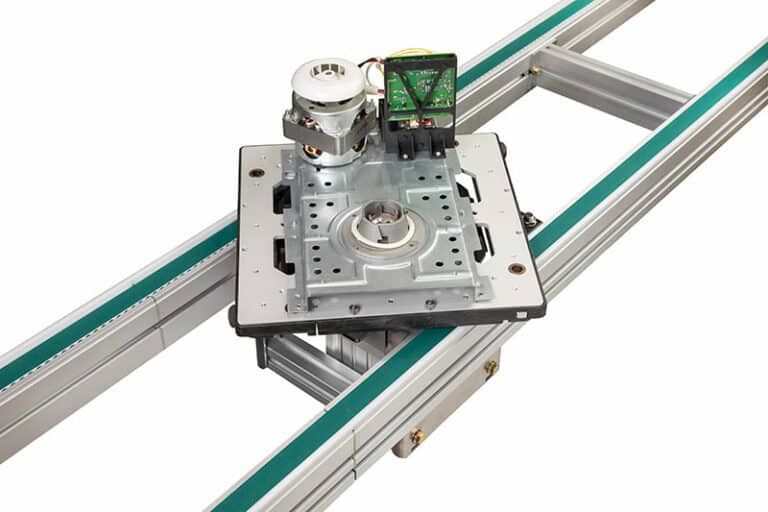

ERT150 Pallet System

The ERT’s lightweight, open frame design makes it an ideal option for highly precise and delicate production operations such as pharmaceuticals, batteries, and electronics. With precise product movement and positioning, this conveyor integrates seamlessly with automated processes and robotics.

ERT250 Pallet System

The heavy duty ERT250 pallet system offers the same open frame edge roller design as the ERT150, but with an increased capacity for large scale automated processes. This customizable conveyor is perfectly suited for manual and automated assembly processes for electronics, appliances, EV batteries, and more.

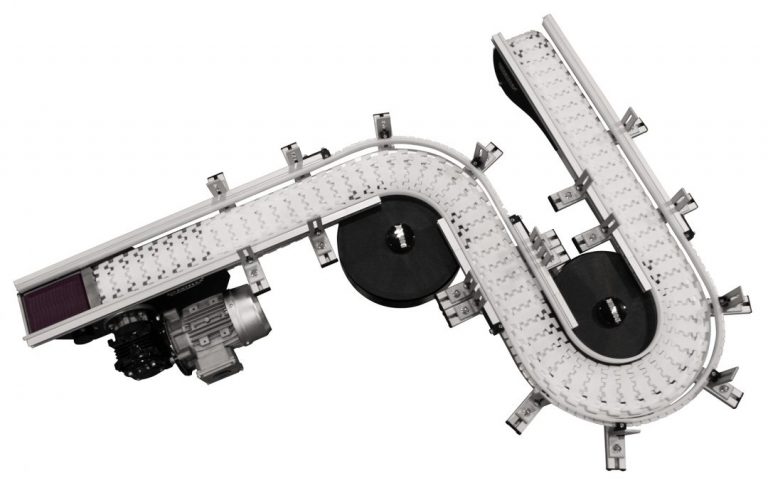

FlexMove Pallet System Conveyors

- Accurate positioning and routing

- Ideal for assembly processes or inspection

- Components sold as kits to allow for easy design changes and layout flexibility

DualMove Timing Belt Pallet System

Our highly advanced DualMove Pallet System for assembly automation is ideal for increasing efficiency, generation, and precision of pallet traffic. Additionally, it reduces downtime costs that could disrupt production.

Best For:

- Medium to large sized part movement

- Product routing and control

- Product inspection

- Assembly automation

FlexMove Conveyors

1100 Miniature Conveyors

2200 Belted Conveyors

- Stronger, improved frame design

- New frame widths with single piece frame for widths 12″ and under

- Improved bedplate durability with hard anodized frame coating

- Universal T-slots fit industry standard hardware

- Updated drive and idler tails for easier belt install and shaft position change

- New 5/8″ high speed nosebar with speeds up to 200 fpm

- Adjustable guiding with new modern design and improved clamp method

- New guide accessories

- New belt options

2200 Modular Belt Conveyors

- Ladder-style, open frame construction for water and chemical drainage and air cooling.

- All belts fully contained in UHMW guiding for maintenance free tracking.

- Universal T-slot for ease and flexibility of adding accessories using industry available hardware.

- Additional frame widths and expanded guiding and chain options.

- Consolidated motor & control offerings.

2200 Precision Move Conveyors

2700 Medium Duty Conveyors

DCMove Belted Conveyor

3200 Series Conveyors with Intralox Activated Roller Belt™ (ARB) Technology

- Flexibility to handle multiple product sizes without the need for changeover

- Minimizes floor space consumption

- Increased system reliability

- Eliminates costly system controls, reducing complexity

- Encased moving parts provide safer work environments

- Low maintenance solution

- Handles product as small as 6″ x 6″

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy