Allergen control is one of the most critical components of food safety in today’s manufacturing environment. With strict regulations like… Read more »

Category: Sanitary Conveyors

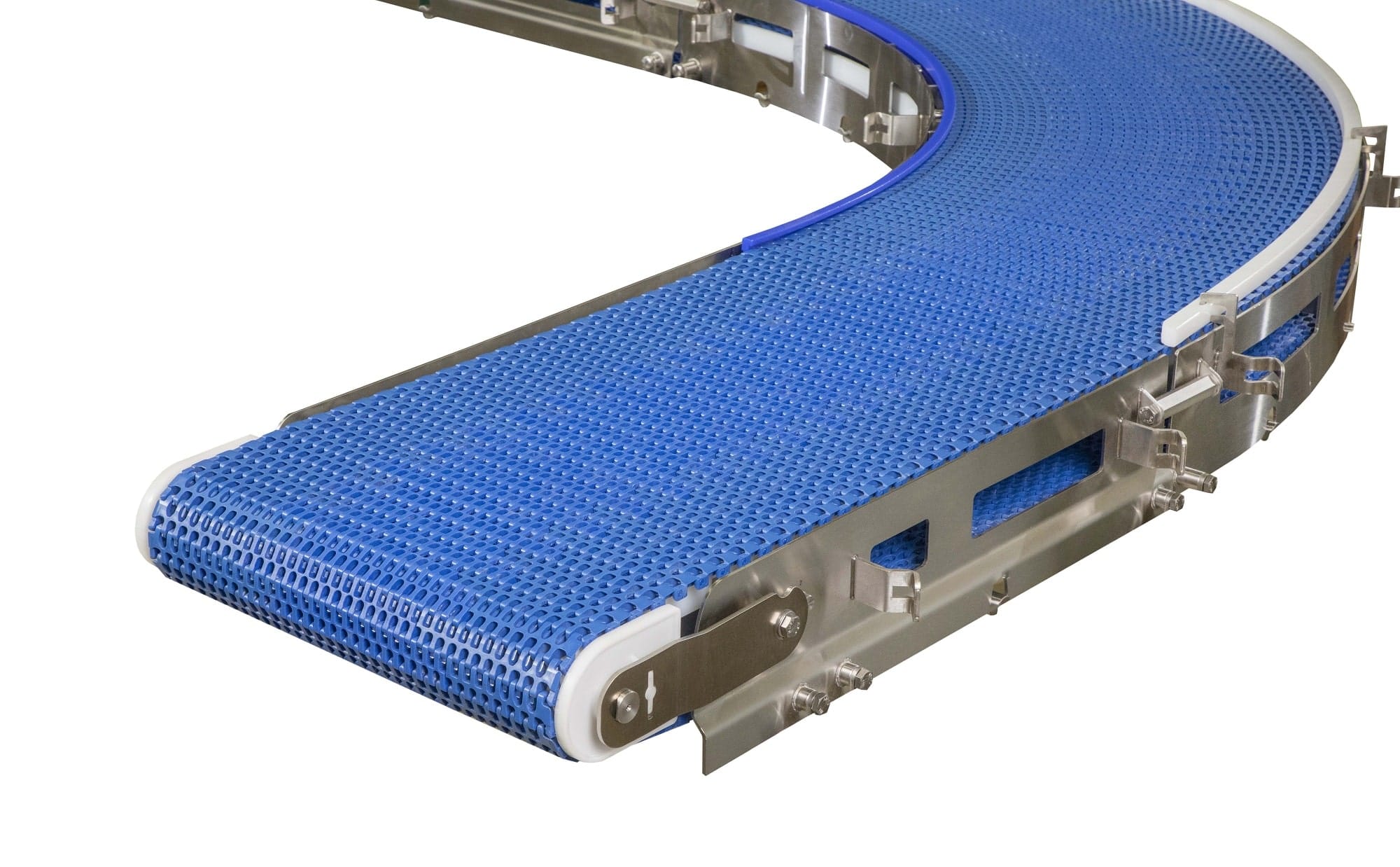

AquaGard GT Q&A

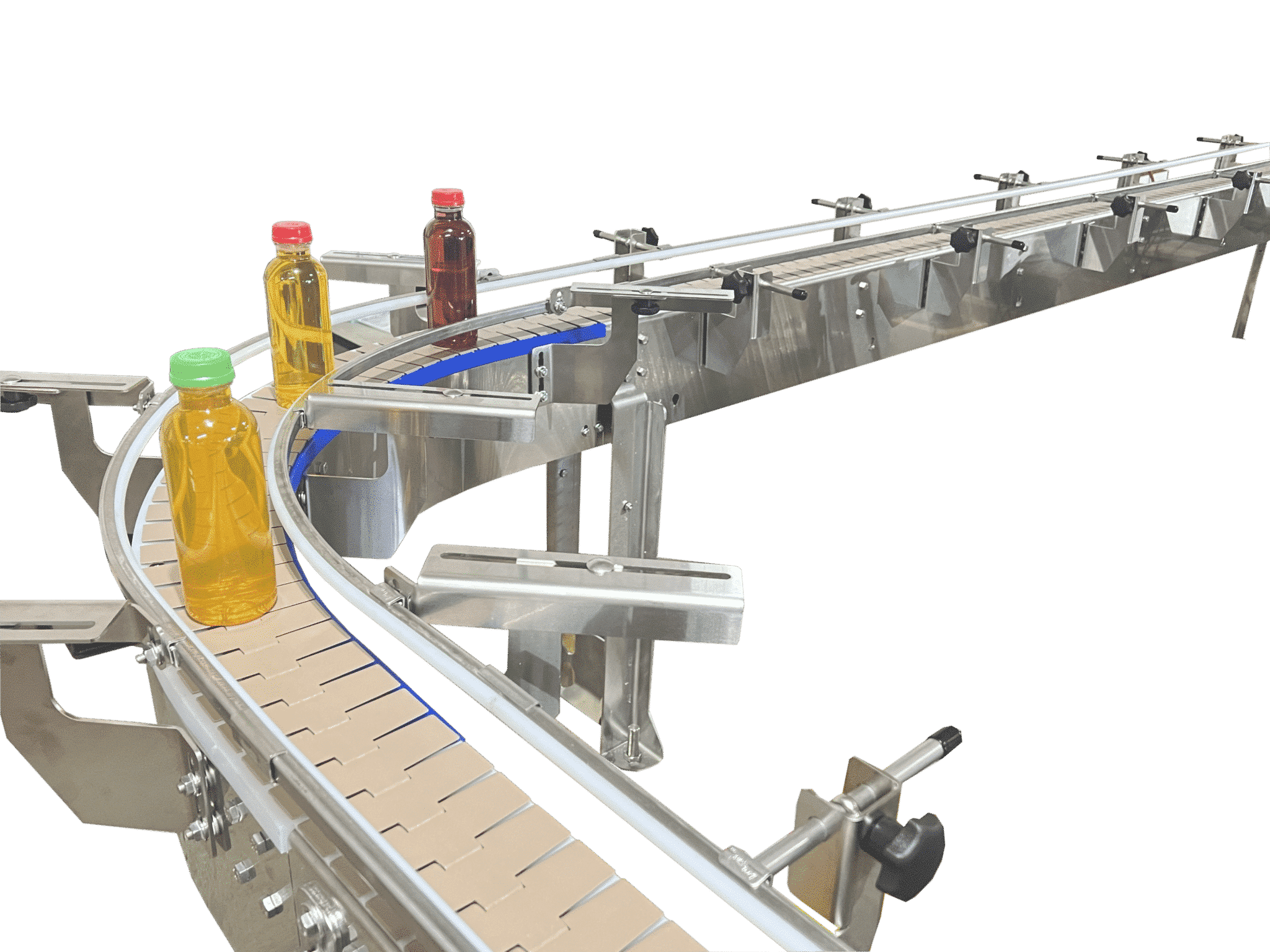

The AquaGard GT offers a truly unique conveyance solution for packaged food and beverage applications. Utilizing a flexible chain belt… Read more »

Enhancing Efficiency and Safety: The Role of Conveyors in Pet Food Manufacturing and Packaging

In the bustling world of pet food manufacturing, efficiency, safety, and precision are paramount. From ingredient processing to inspection and… Read more »

A New Partnership Begins with the AquaGard GT

When it comes to conveyor technology, it’s safe to call both Garvey and Dorner industry leading experts. In 1967 Fran… Read more »

Innovating Hygiene: The Impact of Automated Conveyors on Food Processing

In the ever-evolving food processing and packaging landscape, automation has become more than just a buzzword; it’s a transformative force… Read more »

Enhancing Efficiency in Food Processing: The Impact of Precision Conveyors

In the fast-paced world of food processing, efficiency and precision are crucial elements to ensure the delivery of safe, high-quality… Read more »

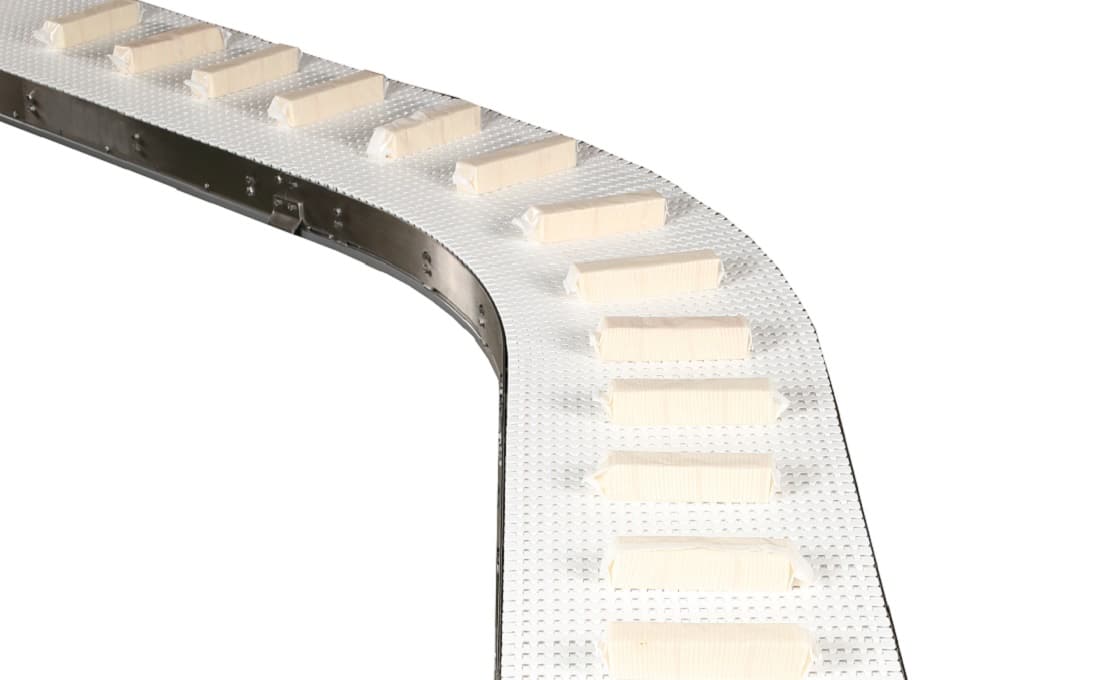

Don’t Take Conveyors for Granted: Four Tips in Selecting Equipment

Conveyors are often one of the most overlooked components within a more extensive snack food, bakery processing, or packaging line.… Read more »

Crafting Quality: How Dorner Conveyors Elevate Craft Brewery Operations

Craft breweries have taken the beer industry by storm in recent years, offering a diverse array of unique and flavorful… Read more »

Improve Line Changeover in Food Production with Dorner’s Sanitary Conveyors

The food production industry has always had to grapple with line changeovers, whether it’s switching to different flavors or a… Read more »

Challenges Facing the Dairy Industry

The economic upheaval in the past few years has facilitated significant change across many industries, and dairy producers are some… Read more »

National Food Allergy Awareness Month with Dorner Conveyors

May is National Food Allergy Awareness Month. At Dorner, we are dedicated to creating quality sanitary conveyors to help our… Read more »

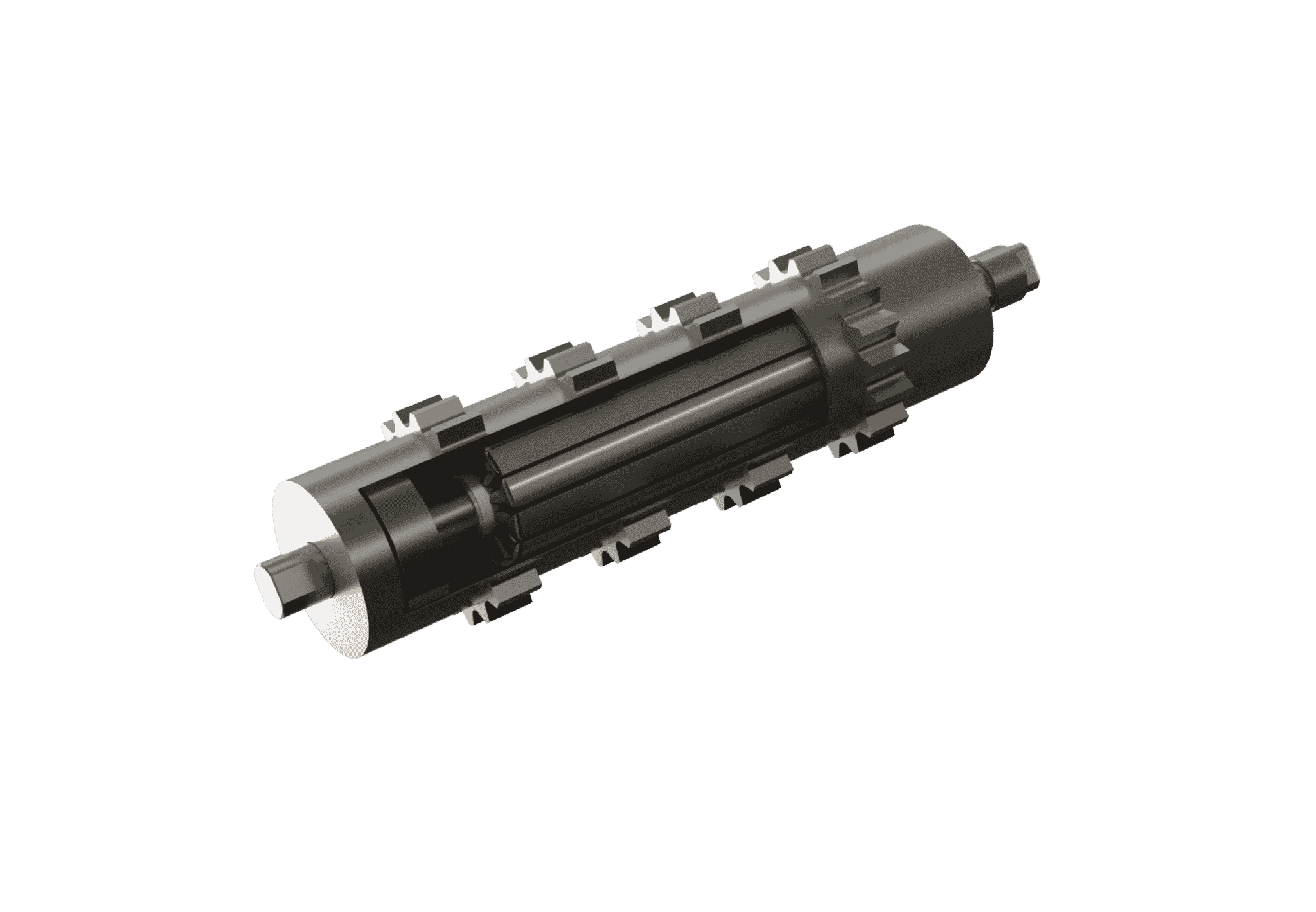

OneMotion – Mag Drive Motors: The Perfect Companion for AquaPruf Conveyors

Dorner partners with many organizations to bring top-of-the-line conveyance products and systems to our customers. In this series, we’re highlighting… Read more »

AquaPruf Ultimate Conveyor Earns 3-A Certification

Dorner’s AquaPruf Ultimate conveyor is now 3-A Certified. Evaluating equipment for 3-A certification is performed by an objective, independent third-party… Read more »

AquaPruf Conveyors in Action

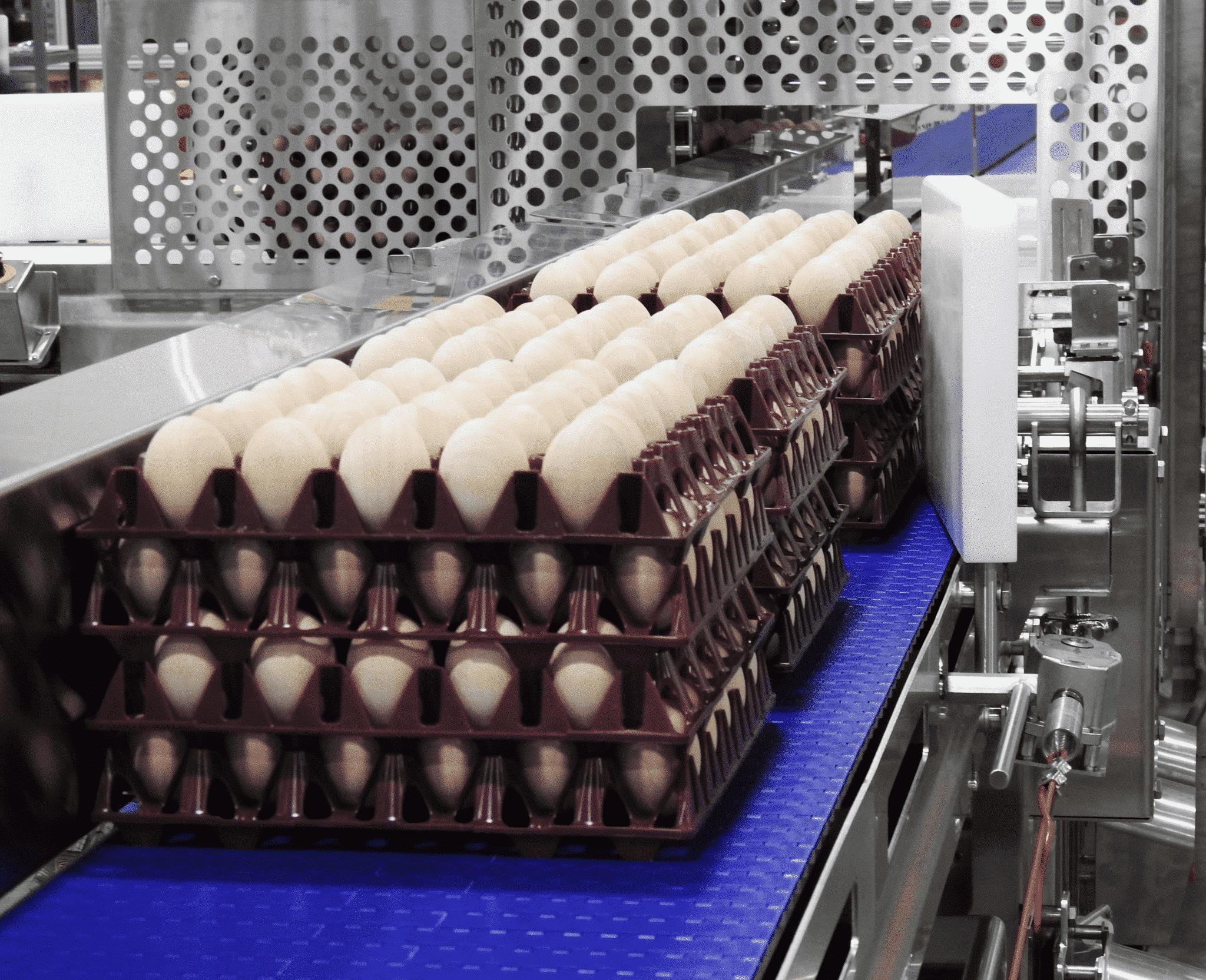

Dorner’s AquaPruf Sanitary Conveyors feature industry leading designs, ensuring the latest technology in food safety. 10 Reasons AquaPruf Conveyors Are… Read more »

10 Reasons AquaPruf Conveyors Are Now Better Than Ever

Dorner’s AquaPruf redesign was based on what our customers told us they need in a stainless steel, sanitary conveyor.… Read more »

Dorner’s Redesigned AquaPruf Conveyor Brings Users the Latest in Food Safety Features

Dorner’s philosophy of constant improvement is shown in its newly redesigned AquaPruf Conveyor, the latest iteration of its popular selling… Read more »

Efficient, Fast, and Aesthetic Preparation: Dorner Conveyor in Kitchen Use

To provide the perfect evening for large parties at the Hotel-Gasthof Adler in Bad Wörishofen, Bavaria, it is essential to… Read more »

Dorner Europe Helps Plan New Production Facility for Poultry Processing Company

Ideally, when a company is designing a new production plant, Dorner is able to assist from the start. This… Read more »

Conveyors Designed for Food and Worker Safety

Food safety is always an important issue when it comes to meat, poultry and all types of food processing. Dorner’s… Read more »

Conveyor with Custom Pack Station Designed for Ready-To-Eat Application

Dorner’s sanitary conveyors are built for food safety. Our systems are easy to clean and disassemble, hygienically designed and safe… Read more »

AquaGard and AquaPruf Conveyors Earn BISSC Certification for their High Sanitary and Safety Attributes

Dorner’s AquaGard and AquaPruf sanitary conveyor platforms have again earned the coveted Baking Industry Sanitation Standards Committee (BISSC) certification… Read more »

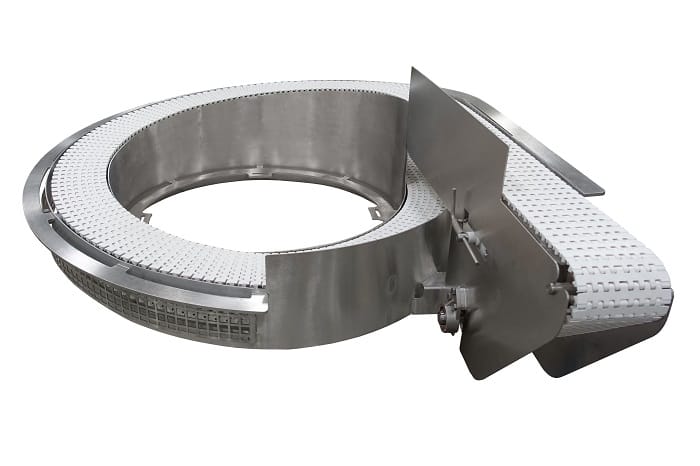

Sanitary Helix Now with Added Features

As we’ve highlighted in the past, Dorner has created Sanitary Helix designs to integrate with Hoosier Feeder’s Food Grade Centrifugal… Read more »

Dynamic Guide Completes Sanitary Merge

Recently, a customer needed to improve their process of merging two lanes of frozen pizzas into a single line. Their… Read more »

Custom Frozen Pizza System

At Dorner, we can provide anything from a single conveyor to a full system. Recently, Dorner worked with a… Read more »