The e-commerce market is fast-paced and continuously growing in demand. At Dorner, we understand the importance of ensuring the… Read more »

Category: Belt Conveyors

3 Ways Conveyors Can Support E-Commerce Success

(This blog was originally posted on Packaging Digest) The pandemic lifestyle has dramatically changed how people work, socialize, and purchase products. For… Read more »

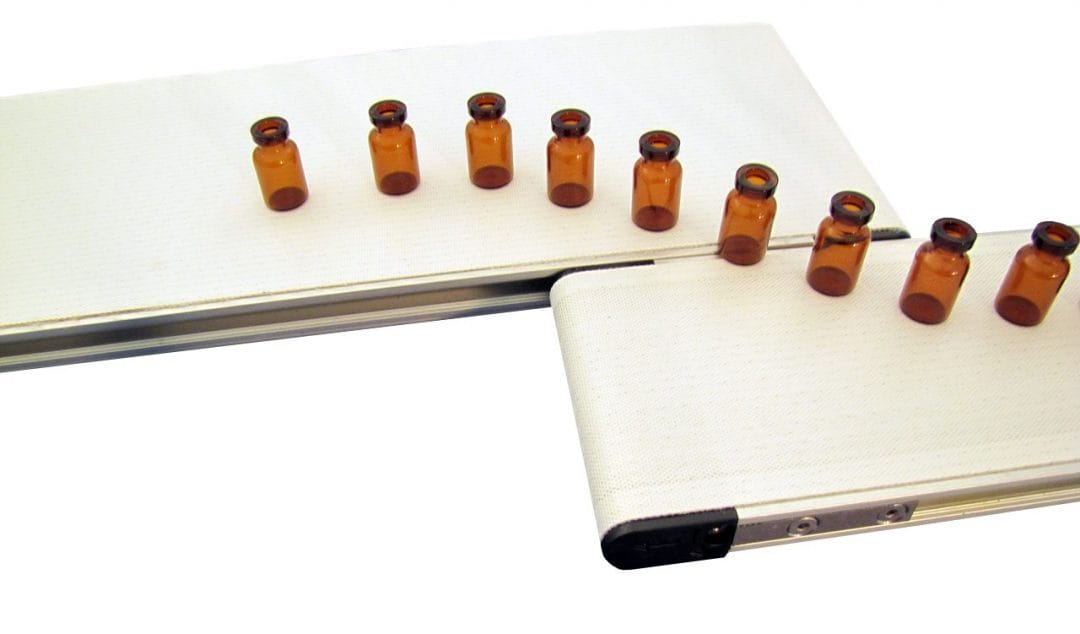

Miniature Conveyors for Any Application

Miniature conveyors are conveyors built as small as they come. And despite their space-saving sizes, these conveyors aren’t short on… Read more »

A Wide Range of Small Conveyors

Dorner offers a wide range of small conveyors designed to move parts and product of all sizes, shapes and weights.… Read more »

Get Started with Conveyor Basics

What is a conveyor? Are you interested in learning more about conveyors, but don’t know where to start? Take… Read more »

Speed Up Your Process with Cleanroom Conveyors

Are changing demands impacting your business? Dorner’s variety of cleanroom verified conveyors* are designed to keep your products and customers… Read more »

Custom Vacuum Conveyors Made In-House

When your products or components are small, lightweight and moving at a steady speed, you need a transfer solution… Read more »

3200 Series Precision Move Conveyors for Guaranteed Accuracy

Dorner’s 3200 Series Line of Conveyors are heavy duty, low maintenance conveyors designed for medium to large sized part handling.… Read more »

Seamless Integration Powered by Precision Move Platform

Recently, a Dorner customer was in the position of needing to automate a product labeling line. The line presented… Read more »

Magnetic Conveyors Customized for Efficiency

Every business needing a magnetic conveyor in its facility has a specific product to run. Therefore, no two solutions… Read more »